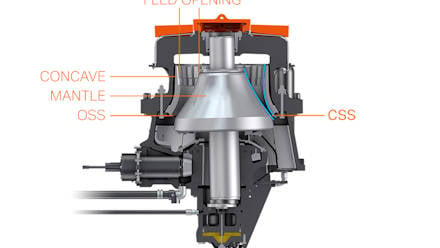

Crushing chambers – cones

Having a good understanding of your crushers helps you make smart, informed decisions. Whether you want to build up your knowledge or refresh your memory, this is the place to start. We take you through the basics of cone crushing to more detailed advice on chamber solutions, feed arrangements and configurations. You can also find links to further reading if you want to go deeper.