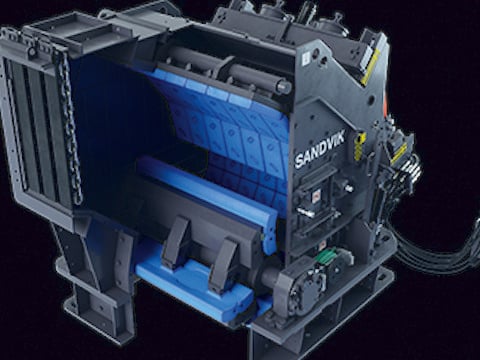

The 700 series of Horizontal Shaft Sandvik impact crushers offers new levels of safety and efficiency. Developed to comply with new EU legislation, you can configure these smart, modular crushers to operate in a variety of applications in either primary or secondary crushing mode.

High reduction ratios

The perfect HSI crusher for primary (feed sizes up to 900 mm) and secondary crushing for limestone, recycling, and cement industries. Achieve 2 stage plants instead of the usual 3 stage plants in aggregate production, resulting in higher uptime and lower cost of ownership from proven horizontal impact crushers that add even better performance and cost savings than before.

Modular intelligence

Built using a modular system, new HSI crushers can be ordered and shipped very fast and you can change between primary and secondary application in less than a day.

Easier & safer maintenance

Safer and easier to use, the new range of HSI crushers has been designed to comply with all upcoming EU health and safety rules.

Sandvik impact crushers get the job done better

Choose from a complete range of options to boost crushing efficiency, extend parts life, and adapt your crusher to meet your exact requirements.

Impact crusher working with even greater performance

High reduction ratios and single-stage crushing for non-abrasive material in the aggregate industry allowing private quarry owners and recycling plants to recirculate oversize to primary, greatly reducing production capital outlay.

- Good product shape — low flake and elongation ratios

- Ability to handle re-enforced steel bars enabling recycling of both steel and aggregate

- Crushing of low abrasive (AI) index materials in aggregate plants

- Ability to recycle old road surfaces (asphalt) for inclusion in new asphalt products

Model |

Weight kg (lb) |

Max. feed size mm (in) |

Capacity tph |

| CI732 HSI Impact crusher | 29,650 (65,367) | 350 (13.8) | 250 - 575 |

| CI731 HSI Imapct crusher | 27,750 (61,178) | 1,000 (39.4) | 400 - 700 |

| CI722 HSI Impactcrusher | 16,256 (35,838) | 350 (13.8) | 150 - 250 |

| CI721 HSI Impact crusher | 16,000 (35,274) | 900 (35.4) | 200 - 400 |

| CI712 HSI Impact crusher | 11,184 (24656) | 300 (23.6) | < 150 |

| CI711 HSI Impact crusher | 11,005 (24262) | 600 (23.6) | < 200 |

-

Commitment through an entire lifecycle

We supply genuine parts, service solutions, extensive training and a wide range of wear, crushing chamber and screening media solutions that deliver lower operating costs, improved product quality and maximum productivity.

-

Reliability and protection package

Unpredictability is the enemy of productivity. The Sandvik Reliability and Protection package is designed to keep you in control of your costs and efficiency at all times. It includes on-site periodic inspections that enable proactive preventative maintenance recommendations, trend analysis, and our exclusive 1 + 2 years equipment warranty – protecting your investment and giving you an improved cost of ownership.

-

The knowledge hub

Over the last 150 years, we've learned a thing or two about crushing and screening. As innovators and experts in the field, we have a deep understanding of technical and mechanical factors, but there’s more to it than that. Find out at our knowledge hub for crushing and screening.