Durability: Whether made from rubber or polyurethane, Sandvik’s tensioned screening media lasts significantly longer than wire mesh alternatives. This can result in lower costs in the long-term, but it also reduces the amount of downtime spent replacing media – providing an opportunity for even greater productivity and profitability. They are designed to be easily installed too, reducing downtime even further.

Customizable: Sandvik’s tensioned screening media is tailored for the specifications of your screen. They are all available in a range of lengths, widths and thicknesses, with other sizes available on request. A variety of hooks are available, for both cross- and longitudinal-tensioning, so they can be attached to almost any screen on the market.

Light: Because they are so much lighter then wire mesh alternatives, all the media in this range are cheaper to transport and easier to install. They are also significantly quieter than wire mesh.

Sandvik currently offer four categories of tensioned screening media, all with several customization options. Here’s a quick summary.

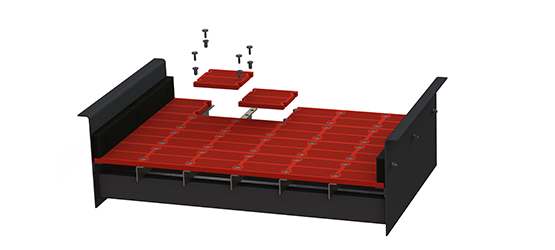

WX6000 Tensioned screening media

These rubber panels are designed for screens with cambered decks and support bars, to be used for fine to medium coarse dry screening (separations between 5.6 and 63mm, with a maximum feed size of 150mm). They are suitable for either cross- or length-tensioned screens and their flexibility helps reduce pegging and blinding. Reinforced with polyester cord fabric, they can be optimized either to maximize capacity or to deliver the longest possible wear life.

WX6500 Tensioned screening media

Because of their thinness and impeccable design, this range of screening offers the accuracy of wire mesh, along with all the benefits of rubber: durability, low-weight, low-noise, and with less pegging and blinding. They deliver high accuracy for fine screening (2 to 32mm separations).

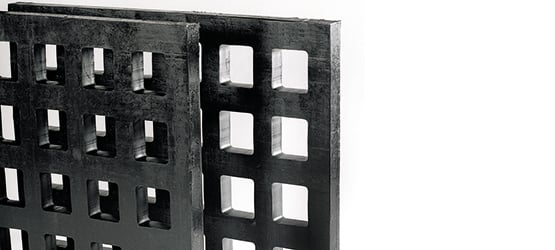

WX7000 Tensioned screening media

The WX7000 range offers an outstanding combination of long-life and anti-blinding properties. Made from polyurethane with steel wire reinforcement, they stay clean and resist blinding, even in difficult condition. These are your best choice for fine screening 2 to 16mm material where fines are combined with moisture. They can have a lifetime of up to 20 times longer than wire mesh alternatives, they have a large open area, and they’re designed with dam bars for increased accuracy.

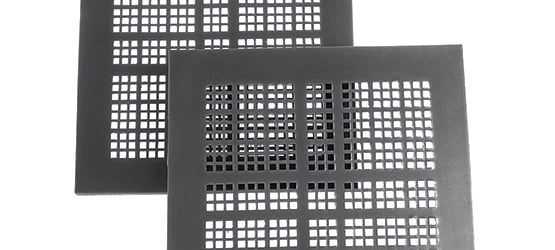

WX8500 Tensioned screening media

These are made from polyurethane with molded holes, so they offer the benefits of the other Sandvik tensioned media range, but in a material that is especially effective for fine to medium screening in wet applications.

Read more about Tensioned screening media