A central hold-down bar could be used to help keep the screening media firmly in place, in which case the deck will have a double-crown, with the bar running along the valley between the two crowns. The bolts on the side rails are tightened to provide tension across the screening media.

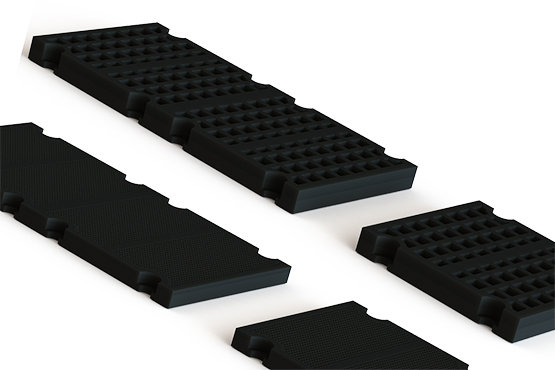

That describes the most basic setup, but a massive amount of variations can be made on this model. For example, the material can be length tensioned rather than side tensioned. This means rails at the entry and exit of the screen are used to tighten it. Then there is an ever-expanding range of materials that can be used, including various alloys of steel, polyurethanes and rubber.

One of the main advantages of using a simple wire mesh is that, because of the thinness of the wires, it has a large number of holes. On the other hand, wire mesh is prone to pegging (when material lodges in the apertures of the screen), so any efficiency gains may be short-lived. Similarly, wire meshes may be the cheapest screening material available, but they are likely to wear out quicker than a rubber or polyurethane alternative, so it may be a more expensive option in the long run.