What happens in the screen box?

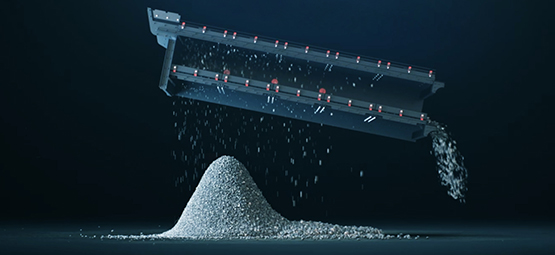

Multi-slope, inclined, horizontal, free fall, grizzly. Mechanical screens come in a variety of shapes and sizes, but there are a number of basic processes that take place in every type of screen.

The surfaces that contain the screening media – with the upper deck having larger openings than the bottom deck. This construction can separate feed material into three fractions – throughput, which passes through all the decks in the screen, and two overflow piles which contain material that has passed through one or none of them.

There are two directions of movement involved here. The material moves forward along the screen decks. At the same time, smaller particles travel vertically through the material bed and the screening media. These movements are prompted by vibrations, which are caused by the mechanism in the image. Depending on the fraction size and material, different types of vibration are appropriate. For fine screening, for example, a linear motion is likely to be more effective than circular motions.

Through a combination of these movements and the pull of gravity two processes take place, stratification and separation. Stratification can occur on the screen deck, the feed box or plate, and even on the conveyor that lifts the material up to the screen. It is simply when smaller particles flow downwards between larger ones. The vibrations in the screen create a fluid state on the bed, encouraging stratification and making the second process – separation – possible.

In the separation process, particles smaller than the apertures on the screens fall through to the lower deck or onto the throughput pile.

It’s important to understand that it is practically impossible to achieve perfect separation through screening – there will always be a small proportion of undersize and/or oversize material that finds its way into each fraction. Larger screening areas, extra decks and different types of vibration can increase the accuracy of the screening process, but these invoke extra costs. With this in mind, you can think about the screening process in terms of two competing priorities – the accuracy of the final fractions against the resources that you employ to achieve it. The aims of your overall operation will determine how you balance these priorities.