Crusher automation

ACS-c 5

Powerful automation without the complication

Introducing the new ACS-c 5 for Sandvik 800i cone crusher series – our most powerful user-friendly automation system to date. By integrating the powerful capabilities of all crusher modules and subsystems into a single automation system, we’ve made 800i crushers easy and intuitive to use.

Designed around the needs of the people who use them

The latest 800i crushers with new ACS-c 5 combine simple yet robust mechanical design with powerful user-friendly automation to better support diverse operational roles. The new role-based interaction functionality facilitates the work of operators, maintenance personnel, and engineers by offering guidance, access to valuable data, and tools for proactive maintenance and optimization.

Clarified responsibility with role-based interaction

Operator

- The automation system guides the operator through alarms and recommended actions, streamlining the decision-making process during alerts and minimizing the impact of potential issues

- This guidance helps operators achieve their targets without the concern of losing shifts due to downtime

- Easy access to manuals facilitates quick self-help, empowering operators to address issues independently and efficiently

Maintenance

- The maintenance personnel have access to an improved historical and operational data log, providing a comprehensive overview of the crusher’s performance

- The inclusion of 90-day historical logs allows for in-depth analysis and tracking of the equipment’s performance over an extended period

- Advanced tools aid in defining, improving, and updating maintenance schedules, contributing to more effective and proactive maintenance practices

Process/reliability engineer

- The new automation system offers engineers more opportunities to monitor, analyze, and optimize the crusher’s performance

- The ability to create crusher programs and fine-tune system limits allows for a more customized and optimized operation

- Performance optimization through insights on feed conditions, load cycles, pressure distribution and uncrushable objects

- Proactive warnings generated by the system help prevent unplanned maintenance downtime, enabling service engineers to address issues before they escalate

This is ACS-c 5

One system for complete crusher control

- Process and equipment focus, all in one user interface

- One modular system for monitoring and controlling all crusher sub-systems

- All sensors in collaboration for protection, predictions and maintenance planning

Tools to simplify troubleshooting and optimization

- Alarms with recommended actions to reduce downtime

- Instructions with search feature

- Alarm and event logs to find connections and recurring problems

- Historical trends for analyzing data

- Unlimited logging of calibrations and daily operational data

- Easy-access to your digital manuals

Full supervision and remote control with seamless integration to plant

- Prepared for the most common communication protocols — More than 500 signals available for supervision

- Remote control of all commands needed for operation

- Communication monitoring for secured and safe control — Plant system clock synchronization

Crusher reliability with proven automatic setting regulation

- Based on ASRi system algorithm, continuously improved since 2002

- Intuitive and easy recognition for operators with previous ASRi experience

- Simplifies training and operation

Clarified responsibility with role-based interaction

- Predefined and configurable user levels — Permissions based on responsibility

Increased availability with optimized alarm management

- Alarm classes based on severity-of-consequence and time response needed

- Postponed equipment shut-down and bypass options in case of non-critical alarms

ACS through the years

In 1967, Sandvik introduced our very first automation system to the market. Over the years, there has been a continual evolution of crusher control systems to optimize the performance of our crushers. Explore the ACS evolution.

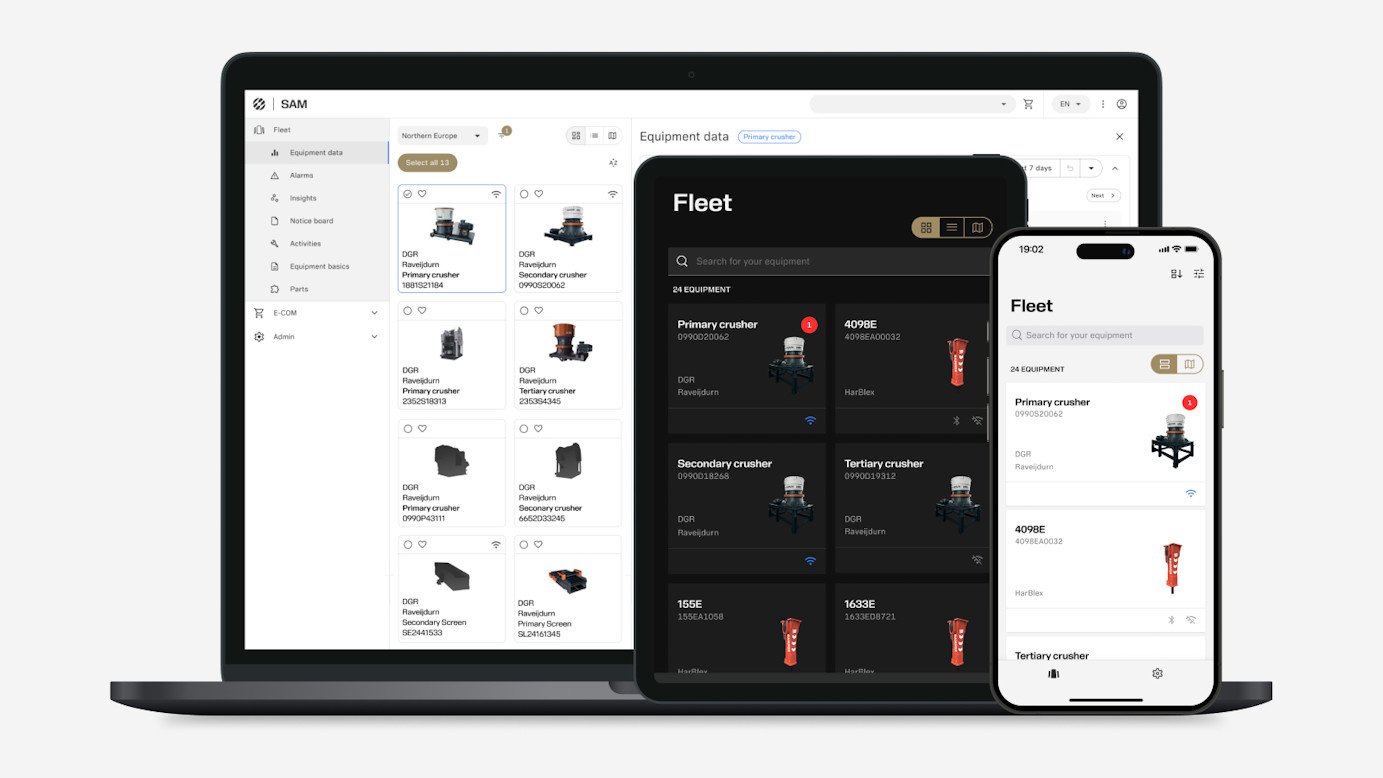

Put more and better data to work for you

800i crushers can be connected to our cloud based digital service – SAM by Sandvik, our ever-evolving digital service designed to support operational excellence in crushing and screening plants. Learn more about SAM by Sandvik

Contact us

We are present worldwide and always here to help.

Get in touch today!