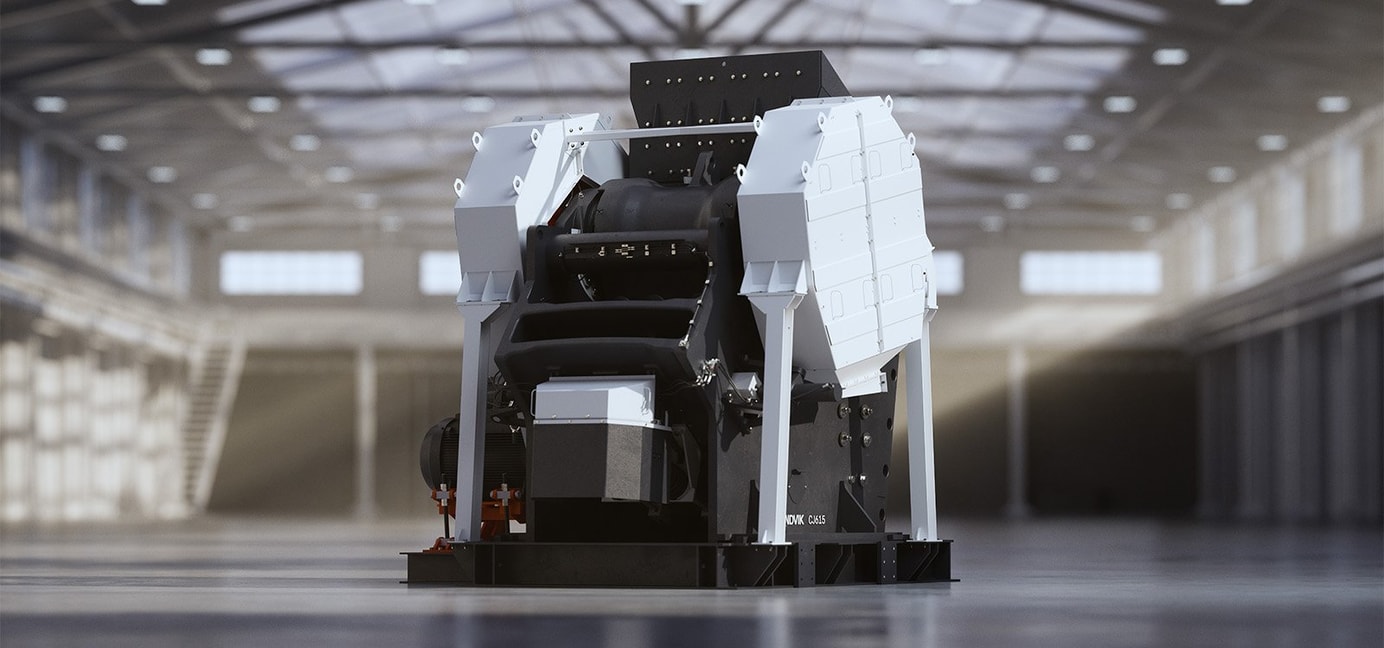

New generation Sandvik jaw crushers

Our jaw crushers come complete with all the advanced features you need for plug-and-play primary and tough material crushing. Secure safety, improve productivity, reduce costs and accelerate sustainability with a partner you can count on.

Better crushing starts here

From the early crushers of 1897 to today’s powerful jaw crushers, Sandvik has continously innovated and built upon an engineering legacy of uncompromising safety, reliability and performance.

Now we’re taking another exciting step towards better crushing—with a new generation of Sandvik jaw crushers, integrating the latest features and bringing even higher Sandvik-grade performance to your crushing operation.

Now more Sandvik than ever

Sandvik jaw crushers now include hydraulic wedge setting with synchronized retraction arrangement for easy and safe crusher adjustment, high energy efficiency main motor, upgraded guarding and clear user-friendly documentation—integrating even more of the safety, performance and sustainability you expect from Sandvik solutions.

Improving our crushing game to empower yours

- Hydraulic wedge setting with synchronized retraction arrangement for fast, easy and safe adjustment during operation

- High energy efficiency main motor ensures an optimal combination of high power, energy efficiency, reduced operational costs and lower carbon footprint

- Compact plug-and-play solution means you’ll be up and running in the shortest possible time with the smallest possible footprint, while ensuring reliable productivity and availability

- 3 years standard warranty

- Clear user-friendly documentation for optimal safety, operation and service

- The latest ACS-j system makes performance and condition monitoring of key metrics simpler through a user-friendly web interface

- Safety-engineered guarding ensures more coverage and complete equipment and personnel protection

- Uniform engineering design for simpler parts replacement and seamless interoperability with all Sandvik solutions

Who you crush with counts

Your Sandvik jaw crusher is backed by the expertise and experience of an industry-leading partner with a crusher innovation legacy going back more than a century. And that has the global installed base and service network to reliably deliver support, solutions and troubleshooting wherever your operation is.

Sustainability starts at the crusher

Sandvik is proud of the positive circularity impact we make through the design, manufacturing and operation of our jaw crushers. From the energy efficiency of our motors to the compact all-in-one footprint to the fully recyclable materials used in their design, manufacturing and operation, Sandvik jaw crushers are a natural fit in sustainable quarry and mining operations.

Sandvik Jaw plates

Sandvik offers four teeth patterns and two alloy selections (M1 and M9) to suit the different types of quarrying and mining applications. Our patterns include Wide Teeth (WT), Corrugated (C), Coarse Corrugated (CC) and Heavy Duty (HD).

The optimal jaw plate selection can be determined based on the rock/ore type characteristics (WI, AI) and the feed characteristics (friction, gradation).

Contact us

We are present worldwide and always here to help.

Get in touch today!